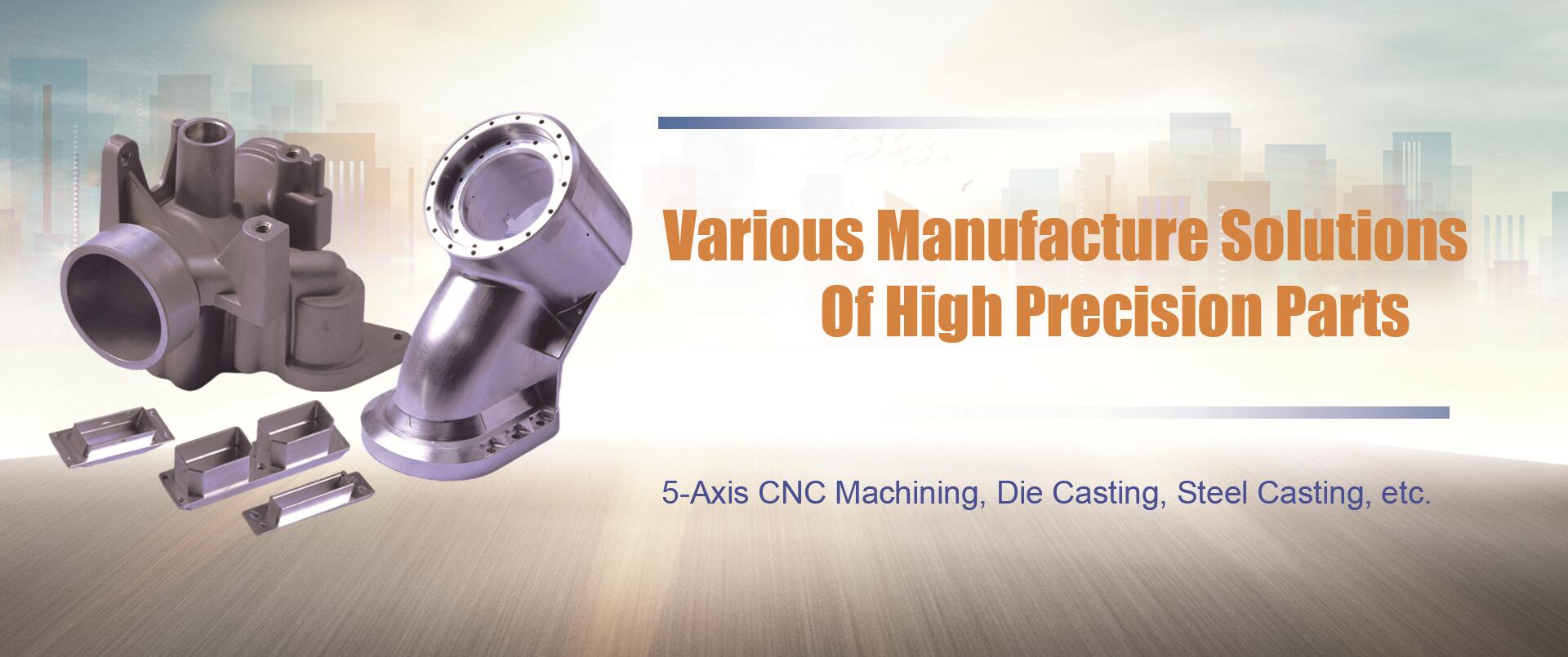

Titanium Accessories - China Manufacturers, Suppliers, Factory

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for Titanium Accessories, Automotive Stamping Parts , Parts , Drop Forging Process ,Brass Accessories . We sincerely welcome close friends to barter company and start cooperation with us. We hope to affix hands with mates in different industries to make a excellent future. The product will supply to all over the world, such as Europe, America, Australia,Nicaragua, Latvia,Salt Lake City, Slovenia.Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

Related Products

Top Selling Products

-

Phone

-

E-mail

-

Top