Aluminum Parts - China Manufacturers, Factory, Suppliers

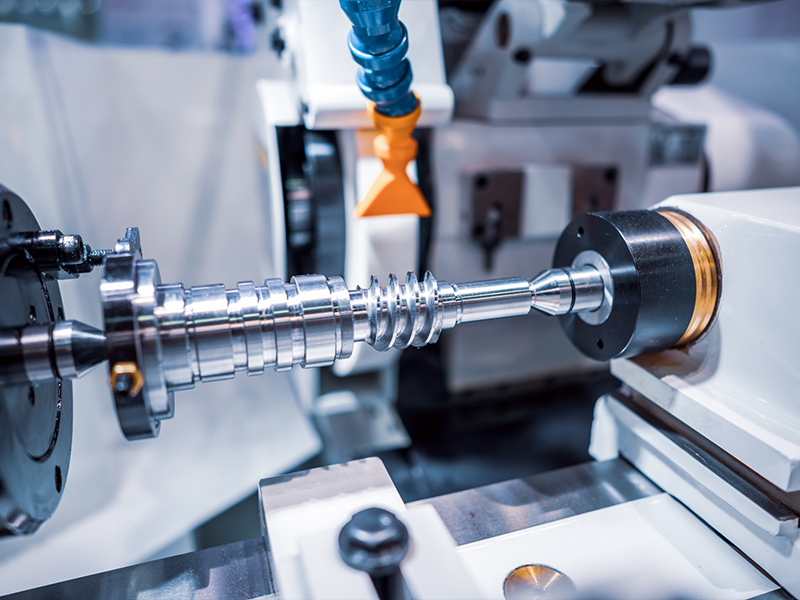

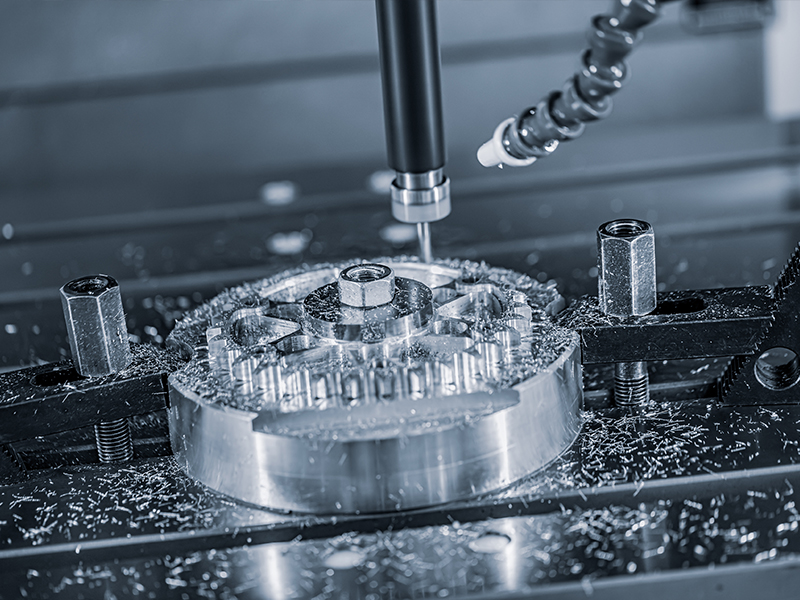

We also supply merchandise sourcing and flight consolidation companies. We now have our very own manufacturing facility and sourcing business. We could present you with almost every kind of product relevant to our solution array for Aluminum Parts, Bronze Accessories , Rapid Cnc Machining , Metal Stamping Process ,Aluminum Turning Parts . And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory! The product will supply to all over the world, such as Europe, America, Australia,Netherlands, Florida,America, Canada.We are proud to supply our products to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Related Products

Top Selling Products

-

Phone

-

E-mail

-

Top